Is It Worth Paying More for Marine Grade Plywood?: “Built to battle moisture, marine plywood isn’t just wood — it’s a promise of durability.” When working in woodworking and construction, selecting the correct plywood is either a make it or break it when it comes to how long a project lasts. It can be a kitchen cabinet, a bathroom vanity, or a boat deck; moisture is a concern in all these situations. In comes marine grade plywood at that moment, with its greater strength, water resistance (water proof actually) and durability that lasts long.

However, its high-end features come with an apparent increase in prices, which begs the question of whether paying that much is worth it in the end. When builders and homeowners are considering their options, it is not only the cost question, but also performance, durability, and peace of mind. Is it wise to save upfront and risk repairs later, or is spending more now the smarter move in the long run? In this blog, we dive deep into the question, “Is It Worth Paying More for Marine Grade Plywood?”

What Is Marine Grade Plywood?

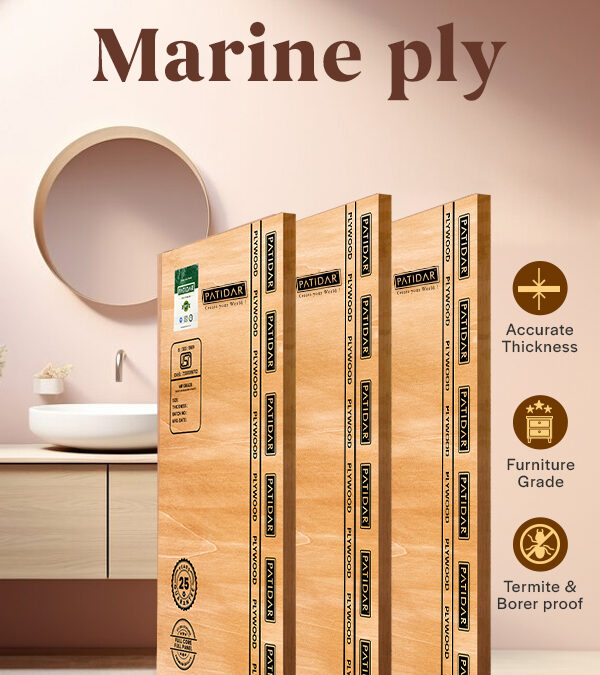

Marine-grade plywood refers to plywood of the finest quality, where the plywood is manufactured using very high-quality hardwood and waterproof adhesive. It is especially made to resist moisture, humidity, as well as direct contact with water and that too without delamination or rotting effects.

Marine plywood has no gaps, soft spots, or core holes like normal plywood. This makes it stronger as well as makes it durable even in a wet environment.

How Is Marine Plywood Different from Regular Plywood?

Many Marine Plywood Manufacturers In India that manufacture tough and wet plywoodas well as normal plywood which is used on the inside or in dry locations. This is where they differ in terms of strength, water resistance, durability and yes, their price. A brief comparison to help you choose one or the other:

| Feature | Marine Grade Plywood | Regular Plywood |

| Adhesive | Waterproof (BWP Grade) | Moisture Resistant or Boiling Water Resistant (MR or BWR) |

| Core Quality | Free from gaps or overlaps | May contain voids and soft patches |

| Water Resistance | Very High | Moderate to Low |

| Durability | Long-lasting, even in harsh weather | May get damaged in damp conditions |

| Price | Higher | Lower |

Where Is Marine-Grade Plywood Used?

Due to its durability and resistance to water, the marine-grade plywood is common in:

- Ships and ship construction

- Furniture in the bathrooms and the kitchens

- Outdoor furniture

- Docks and decks

- Wall and exterior doors

Basically, it’s ideal for any place that is exposed to water or high moisture.

Advantages of Marine Grade Plywood

The marine-grade plywood is specifically manufactured to withstand moist temperature, pressure, and time without being weakened. So what are the main advantages of making it a trustworthy option in a wide range of settings?

1. Superb Water Resistance

The marine plywood adhesive is bonded through a phenol formaldehyde resin mastic, locally termed as the BWP (Boiling Water Proof) adhesive. This is a tough adhesive resistant to boiling and hot water as well as humid conditions. This is the reason why marine plywood works so incredibly well in wet places such as bathrooms, kitchens and outdoor environments.

2. High Strength and stability

This kind of plywood is fabricated by the use and combination of the selected hardwood veneers, which are then layered and pressed with a lot of precision. Inside, it has no pits, cracks, or overlaps, and this makes it homogenous in its strength. It is resistant to pressure, and this qualifies it to be used in heavy and tall buildings.

3. No Warping or Swelling

Among the largest problems associated with normal plywood is that it is prone to swelling, warping, or delamination under wet conditions. To overcome these issues, marine-grade plywood can be used as it is of high-quality build and waterproof bonding. Even under wet or moist conditions, it still maintains its shape and smoothness of the surface.

4. Termite and Borer Resistance

Most of the marine plywood available contains special chemicals that the wood is treated with that give resistance to attack by termites and borers. Such extra protection can be more helpful in locations where pests are prone, or where furniture needs to last longer. It preserves the wood, preventing it from damage over the years.

5. Ideal for Long-Term Use

Marine-grade plywood is made to wear out. It is possible to function relatively low-maintenance in difficult outdoor or high-humidity conditions with decades of service life. As it is resistant to water, insects and wear, the material is valuable in terms of long-term investments in furniture, building constructions and marine.

Is It Worth the Extra Cost?

This is how you can make your decision:

It is worth it: yes, provided:

- You are constructing a kitchen, bathroom, or outdoor furniture.

- The humidity or rainfall in your region is high.

- You desire durability that will last long and fear no damage caused by water.

No, there is no point in it, in case:

- The plywood will be utilised in dry rooms, such as bedrooms or ceilings.

- You have a low budget, and you can use BWR grade plywood.

- You do not require the same level of strength and resistance to water.

For anyone wondering, Is It Worth Paying More for Marine Grade Plywood?, this section should help settle the debate by aligning your needs with its benefits.

Tips Before You Buy Marine Plywood

Always check the ISI mark IS:710 so as to ascertain marine grade.

- To check the presence of branding and embossing on the plywood.

- Request the dealer to provide a test certificate or a treatment certificate.

- Get quotes of at least two reputable suppliers.

- Avoid inappropriate use of Boards sold as marine without certification, usually cheap plywood.

Conclusion

Certified marine plywood is not just a high-quality product—it is a guarantee of reliability, functionality, and future safety. Whether for boats, bathrooms, or outdoor furniture, always choose plywood that meets Top Standards & Certifications for Quality Marine Plywood in India.

Don’t forget to check for IS:710, BWP-grade resin, and buy from ConforPly, a trusted suppliers of Marine Plywood in Yamunanagar to ensure durability and performance that lasts.