Which are the Top Grades of Marine Plywood Explained?: What makes some wood survive storms, splashes, and steam, while others simply fall apart? The answer lies in the wet and humid conditions without swelling, cracking, or weakening. It’s widely used in the type and grade of marine plywood you choose. Marine plywood is specially made to handle boat-building, kitchens, bathrooms, and outdoor furniture—but not all marine plywood is the same. It comes in different grades, each offering a different level of quality and performance.

The global marine plywood market was worth over USD 9 billion in 2022 and is growing at a steady pace of around 5% per year. Today, because houses, coastal properties and businesses need waterproof and durable materials, selecting the proper grade is essential. We will discuss Which are the Top Grades of Marine Plywood Explained? in this blog, to help you make the right choice for your next project.

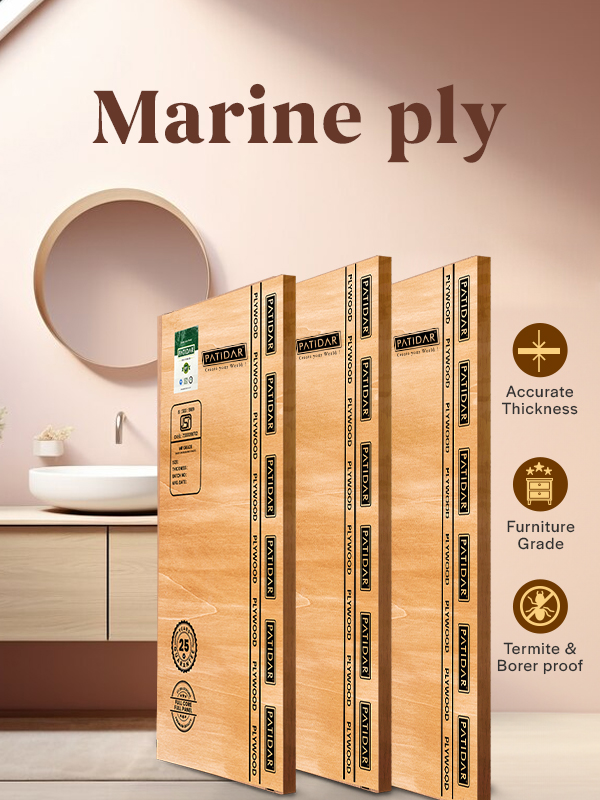

If you’re looking for a Marine Plywood Manufacturer In India that offers a full range of plywood grades and unmatched durability, understanding these grades is your first step.

A Simple Overview of Top Marine Plywood Grades

Here’s an overview table of the marine plywood grades with a simple title and intro line to help readers quickly understand their differences:

| Grade Name | Key Features | Best Use |

| BWP (Boiling Water Proof) | Highest water resistance; lasts long; ISI certified | Boats, bathrooms, kitchens, and outdoor furniture |

| BWR (Boiling Water Resistant) | Good water resistance; less strong than BWP | Kitchen cabinets, semi-wet indoor furniture |

| MR (Moisture Resistant) | Resists humidity but not water; cheaper option | Dry indoor furniture like wardrobes and shelves |

| Gurjan Marine Plywood | Made from strong Gurjan hardwood; premium quality | Luxury furniture, boats, and heavy-duty marine use |

| Calibrated Marine Plywood | Uniform thickness; smooth surface for precise work | Modular kitchens, CNC furniture manufacturing |

| Fire-Retardant Marine Plywood (FR) | Resists fire and water; added safety | Commercial kitchens, hotels, and fire-sensitive areas |

| Flexible Marine Plywood | Thin and bendable; waterproof | Curved boat parts, decorative furniture |

| Phenolic Marine Plywood | Coated with phenolic film, tough and chemically resistant | Industrial flooring, scaffolding, and heavy use |

| Anti-Termite Marine Plywood | Treated to prevent termite damage | Outdoor use in termite-prone areas |

| Exterior Grade Marine Plywood | Water-resistant but less strong than BWP | Garden furniture, outdoor sheds, and wall panels |

Best Marine Plywood Grades for Every Use Explained

Confused about Which are the Top Grades of Marine Plywood Explained? This guide breaks down the best grades for every type of use, from kitchens to boats!

If you’re uncertain Which is the Best Grade of Bonded Marine Plywood, this article will help. The guide explains which grades are useful for all purposes, whether cooking, boating or other crafts.

1. BWP Grade (Boiling Water Proof) – The Best Quality

You cannot fibnd better plywood for boats on the market than BWP. It is built to be sturdy and unchanged after being boiled in water for three full days. In addition, it is certified with the ISI 710 mark which shows it has excellent quality.

- Stays healthy in places that are wet, humid or hot

- It will not swell or crack even after years of wear.

- Designed for use in water most of the time

2. BWR Grade (Boiling Water Resistant) – Good for Semi-Wet Areas

Water will not easily damage BWR plywood, but BWP handles it even better. It takes about 8 hours for the tea to lose its flavor in boiling water. Kitchen cabinets and shelves close to sinks can both benefit from it. It makes use of top-grade glue and hardwood, yet is not quite as resistant as BWP.

- Good for use in areas that remain damp inside.

- Not as expensive as Boglioli, but it’s still rain-resistant.

- Great for use in the kitchen and in partially humid rooms

3. MR Grade (Moisture Resistant) – Not Real Marine Plywood

MR plywood resists moisture and humidity, yet it is not completely waterproof. Glue is used and this weakens if left exposed to water too long. MR plywood is the correct choice for making dry indoor cabinets, wardrobes and TV units. This is not suitable for bathrooms, kitchens or use in the outdoors.

- Suitable for unfinished dry furniture in your home.

- Suitable for dryer areas at a lower cost

- Can’t be used in wet or humid surroundings.

4. Gurjan Marine Plywood – Strong Hardwood Plywood

Plywood called Gurjan is made using hardwood that is both strong and dense, called Gurjan. Most of the times, it lives up to or exceeds BWP’s strict standards. This plywood is made to last significantly longer than other kinds. People use this fiber in luxury furniture, boats and parts of buildings that deal with water.

- Rock hard due to its very strong and dense nature

- Suitable for fine furniture and areas near water

- Makes the surface shiny and even.

5. Calibrated Marine Plywood – Smooth and Even Thickness

Machine sanding smooths each side of calibrated plywood to make them even in thickness. The smooth finish of plywood makes it right for exact work like building modular kitchens and wardrobes. Since BWP or BWR glue is usually used, it comes out water-resistant.

- Even thickness makes it easy to cut and fit the board.

- Ideal for both modern furnishings and CNC manufacturing.

- This looks well built and organizes neatly.

6. Fire-Retardant Marine Plywood (FR Grade) – Safe from Fire

This type of marine plywood has been made to resist fire, without losing water resistance and sturdiness. It is applied where fire safety matters such as in hotels, on ships and in kitchens.

- Helps block the growth of a fire.

- Continues to shield against water and keep the watch durable

- Essential to use in places with a high risk of fire.

7. Flexible Marine Plywood – Bends Without Breaking

It is possible to bend and shape flexible plywood without it breaking. Some areas of lamination involve forming curvy shapes, as with boat parts or creative furniture. Still using waterproof glue and solid wood, this method is strong.

- Perfect for round or curved designs

- Stays waterproof even when you bend it

- Furniture and areas within boats are decorated with this style.

8. Phenolic Marine Plywood – Tough and Chemical-Resistant

Phenolic plywood is coated with a film that guards it from water, chemicals and wear. This kind of rubber is difficult to work with and typically found in industries on scaffolds or truck floors.

- It is tough against water and various chemicals.

- Lasts a long time and remains strong

- Suitable for use in heavy industries

9. Anti-Termite Marine Plywood – Protects Against Termites

This plywood is treated to keep termites and insects away. Termites damage wood, especially in hot, humid areas. Anti-termite plywood lasts longer outdoors and underground.

- Protects against termite damage

- Good for termite-prone areas

- Adds durability in tough conditions

10. Exterior Grade Marine Plywood – For Outdoor Use

Exterior grade plywood is made for outdoor use with rain and sun exposure, but not continuous water. It is water-resistant and weatherproof, but usually less costly than BWP. It’s good for garden furniture, sheds, and wall panels.

- Suitable for outdoor furniture and structures

- Resists rain and sun damage

- Affordable option for outdoor projects

So, next time you ask yourself Which are the Top Grades of Marine Plywood Explained?, refer to this complete guide to avoid confusion and choose wisely. Still unsure? Just remember: quality, moisture resistance, and use case matter the most when picking marine plywood.

Whether you’re sourcing material for furniture, kitchen cabinets, or boat building, always choose a trusted Plywood Manufacturer. And if you’re building doors for dry interiors, look for a reliable Flush Door Manufacturer In India to ensure strength, finish, and long-term performance.